RQC MACHINE

RQC MACHINE Specification

- Product Type

- RQC Machine

- General Use

- Rubber Quality Control

- Material

- Mild Steel

- Type

- Testing Equipment

- Capacity

- 1000 kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Cooling System

- Air Cooled

- Purity(%)

- 99.9%

- Production Rate

- Continuous

- Dew Point

- -40C

- Air Consumption

- 500 L/min

- Pressure

- 7 Bar

- Power Consumption

- 2.5 kW

- Weight (kg)

- 650 kg

- Voltage

- 220 V

- Dimension (L*W*H)

- 1200 x 850 x 1700 mm

- Feature

- High Accuracy and Durability

- Color

- Blue and White

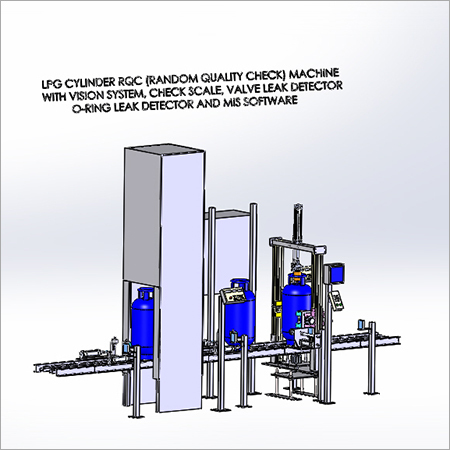

About RQC MACHINE

RQC MACHINE is a high-performance random check industrial system that is designed and developed using advanced technologies and heavy-duty engineering materials. It is equipped with various test units such as a checkweigher, leak detector, vision system, and others to determine the quality of LPG cylinders passing through this test machine. It is also provided with a robust conveyor which to easily move filled cylinders with high safety and zero labor force. The offered RQC MACHINE can be delivered to our clients as per their requirements with an assurance of fast and safe delivery at a reasonable and low price.

Advanced Digital Touch Screen Display

The RQC MACHINE boasts a user-friendly digital touch screen interface, allowing operators to easily manage and monitor tests in real time. Its PLC control enhances accuracy and efficiency, ensuring seamless performance during rubber quality evaluations. Data logging and report generation functions further simplify record keeping.

Precision and Reliability

Engineered for superior precision, the RQC MACHINE achieves a testing accuracy of 0.01% and maintains a purity of 99.9%. Its steady performance is maintained across a wide operating temperature (5C to 45C) and humidity range (10% 90% RH), with safety features like overload protection and emergency stop ensuring operator safety throughout the process.

Robust and Convenient Design

Made from high-quality mild steel, the machine offers durability and robustness. With floor-mounted installation and compact dimensions (1200 x 850 x 1700 mm), it fits efficiently within production environments. Export-grade wooden packing ensures safe transport, and both onsite and remote service support are available for hassle-free maintenance.

FAQs of RQC MACHINE:

Q: How does the RQC MACHINE ensure accurate rubber quality testing results?

A: The RQC MACHINE employs a PLC-controlled system with a digital touch screen and high-precision sensors, delivering testing accuracy of 0.01%. Its computerized data logging and report generation further maintain the integrity and traceability of results, making it ideal for stringent quality control.Q: What safety measures are implemented to protect operators during operation?

A: This system is equipped with overload protection and an emergency stop feature. These safeguards prevent equipment damages and ensure the operators safety, particularly during high-capacity or continuous testing processes.Q: When is maintenance or service support available for the RQC MACHINE?

A: Comprehensive service support, including both onsite and remote assistance, is available as needed. This ensures minimal downtime and optimal functionality throughout the equipments lifetime.Q: Where can the RQC MACHINE be installed, and what is its footprint?

A: The RQC MACHINE is floor-mounted and designed to fit efficiently into production environments, measuring 1200 x 850 x 1700 mm. The export wooden box packaging facilitates safe delivery to your facility.Q: What is the process for using the RQC MACHINE in rubber quality control?

A: Operators load up to 500 g of sample, adjust the settings on the touch screen, and initiate the automated test. The PLC control ensures precise execution, and after testing, reports are generated automatically for record keeping.Q: How does the computerized system enhance usage and productivity?

A: The computerized nature supports continuous, automatic operation, allowing for data logging and report generation. This not only streamlines labor but also provides comprehensive records for analysis, audit, and regulatory purposes.Q: What are the main benefits of using the RQC MACHINE in an industrial setting?

A: Key benefits include exceptional testing accuracy, high throughput of 1000 kg/hr, continuous and quiet operation, robust safety features, ease of use via digital controls, and comprehensive service support, enabling reliable rubber quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

INTRODUCTION UNIT

Product Type : Introduction Unit

Dimension (L*W*H) : Varies with model

General Use : Industrial Air Separation

Computerized : No

Pressure : 7 8 Bar

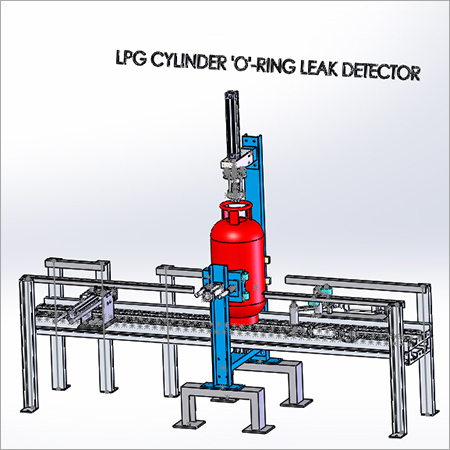

O-RING LEAK DETECTOR

Minimum Order Quantity : 1 Unit

Product Type : Leak Detector for ORing Testing

Dimension (L*W*H) : 400 mm x 300 mm x 350 mm

General Use : For Checking ORing and Rubber Component Leakage

Computerized : No

Pressure : 6 Bar Maximum (Test Pressure)

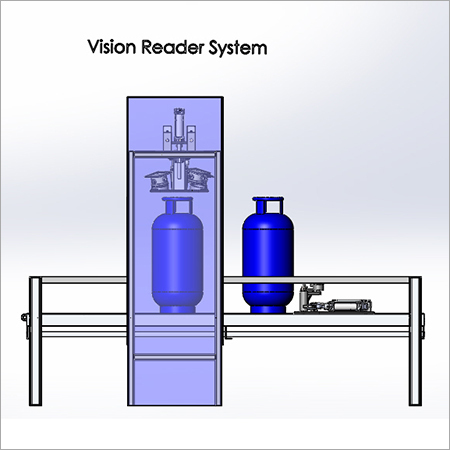

Vision Reader System

Minimum Order Quantity : 1 Unit

Product Type : Vision Reader System

Dimension (L*W*H) : 750 x 550 x 600 mm

General Use : Industrial Vision Inspection

Computerized : Yes

Pressure : Standard

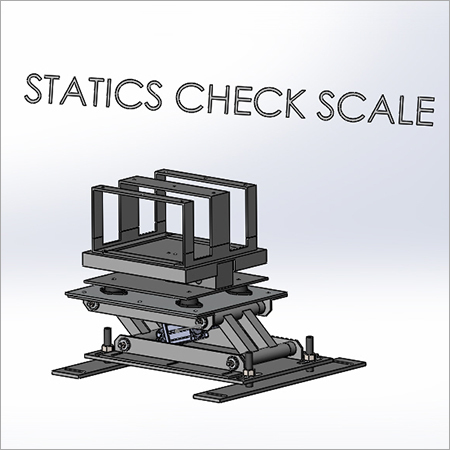

Check Scale 2020

Minimum Order Quantity : 1 Unit

Product Type : Check Scale

Dimension (L*W*H) : 550 x 450 x 780 mm

General Use : Industrial Weight Checking

Computerized : No

Pressure : Standard Atmospheric

Send Inquiry

Send Inquiry