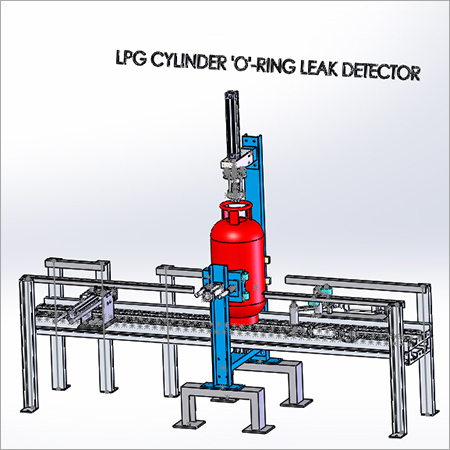

O-RING LEAK DETECTOR

O-RING LEAK DETECTOR Specification

- Product Type

- Leak Detector for O-Ring Testing

- General Use

- For Checking O-Ring and Rubber Component Leakage

- Material

- Stainless Steel and Aluminum Body

- Type

- Bench Top Model

- Capacity

- Up to 5 Samples per Cycle

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual Control Valve

- Production Rate

- Up to 60 Tests/Hour

- Air Consumption

- Approx. 6 L/min

- Pressure

- 6 Bar Maximum (Test Pressure)

- Power Consumption

- Not Required (Pneumatic)

- Weight (kg)

- 20 Kg Approx.

- Dimension (L*W*H)

- 400 mm x 300 mm x 350 mm

- Feature

- Easy Operation, High Accuracy Detection, Compact Design

- Color

- Silver & Black

About O-RING LEAK DETECTOR

We are a renowned name that offers premium-grade O-RING LEAK DETECTOR that can be used within LPG bottling plants to check for leakages within filled gas cylinders. It is designed by using advanced tools and technologies that ensure controlled and efficient operation without any risk of damage. It has a rigid mild steel frame to bear heavy loads and harsh industrial conditions. The conveyor system installed within this machine greatly improves work efficiency as well as mitigates the risk of accidents. Get this high-performance O-RING LEAK DETECTOR as per your demands with the assurance of fast and safe delivery.

Efficient Leak Detection Process

This leak detector utilizes dry air to identify leaks in O-rings and rubber components through visual bubble indication. Quick release couplers allow for easy sample placement, and the manual control valve provides user-friendly operation. Designed for high throughput and reliability, the system ensures rapid test cycles and accurate leak identification.

High Precision and User-Friendly Design

Featuring an analog pressure gauge and robust brass & stainless steel fittings, the device guarantees high accuracy in leak measurement. Its silent, compact structure minimizes workspace clutter while allowing for efficient manual control, making it ideal for both production and quality assurance environments.

No Power Needed Pneumatic Operation

The leak detector is fully pneumatic, eliminating the need for electrical power. Operating at a maximum pressure of 6 bar and consuming approximately 6 liters of air per minute, the system offers both energy savings and operational convenienceperfect for environments where plug-free operation is required.

FAQs of O-RING LEAK DETECTOR:

Q: How does the O-Ring Leak Detector identify leaks in samples?

A: The detector uses dry air at controlled pressure. When a sample is inserted and tested, the presence of a leak is visually indicated by bubbles appearing in the test fluidallowing for immediate and precise identification.Q: What types of components can be tested with this device?

A: It is compatible with various samples such as O-rings, rubber gaskets, and rubber moulded parts, accommodating up to 100 mm OD O-rings and fitting up to 5 samples per cycle.Q: When is this leak detector most beneficial for use?

A: The device is ideal for quality control and production testing during manufacturing or inspection stages, ensuring that each rubber component is leak-free before shipment or assembly.Q: Where can the O-Ring Leak Detector be installed or used?

A: Its bench top model and compact dimensions make it perfect for use in laboratories, manufacturing workshops, and quality assurance departments, requiring only standard air supply and no electrical power.Q: What is the process for conducting a test using this detector?

A: Operators simply insert up to five samples using quick-release couplers, set the manual control valve, and pressurize the system up to 6 bar. Any leakage is identified visually on the tester by bubble formation at a sensitivity of 0.05 mm/s.Q: What are the main benefits of using this leak detector?

A: Key advantages include high detection accuracy, easy manual operation, silent pneumatic function, compact design, and fast testing rates of up to 60 samples per hour, all enhancing productivity and reliability.Q: How is the device operated and maintained?

A: Operation is purely manual via an analog gauge and control valve. Maintenance is minimal due to the robust build with stainless steel and aluminum, and absence of electronic components ensures longevity and easy upkeep.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

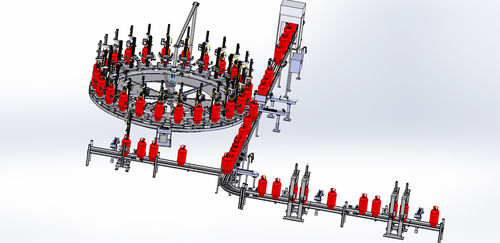

LPG Carousel 10 AND 24 Point

Minimum Order Quantity : 1 Unit

Product Type : LPG Filling Carousel

Power Consumption : 3 12 kW

Feature : Other, High Precision, Robust Design, Low Maintenance, Customizable Points

Dimension (L*W*H) : 3700 mm x 3700 mm x 2200 mm (10 Point); 6400 mm x 6400 mm x 2200 mm (24 Point)

Pressure : 1017 Bar (Working Pressure)

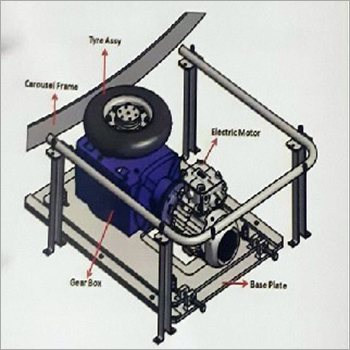

Drive Unit LPG Bottling Plant

Minimum Order Quantity : 1 Unit

Product Type : Drive Unit

Power Consumption : Low

Feature : Other, Corrosion resistant, High performance

Dimension (L*W*H) : 1200 x 900 x 1000 mm

Pressure : High pressure suitable for LPG transfer

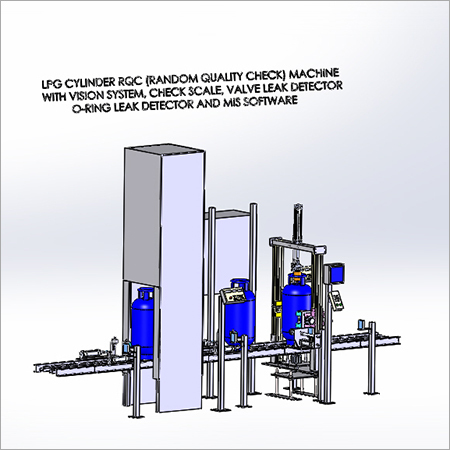

RQC MACHINE

Minimum Order Quantity : 1 Unit

Product Type : RQC Machine

Power Consumption : 2.5 kW

Feature : Other, High Accuracy and Durability

Dimension (L*W*H) : 1200 x 850 x 1700 mm

Pressure : 7 Bar

INTRODUCTION UNIT

Product Type : Introduction Unit

Power Consumption : 8 25 kW

Feature : Other, Skid Mounted, Easy Operation, Energy Efficient

Dimension (L*W*H) : Varies with model

Pressure : 7 8 Bar

Send Inquiry

Send Inquiry