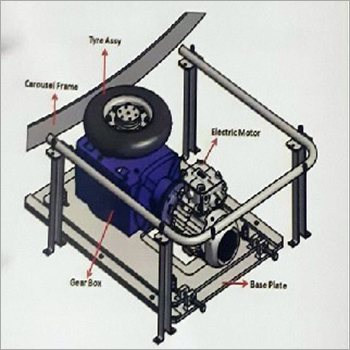

Drive Unit LPG Bottling Plant

Drive Unit LPG Bottling Plant Specification

- Product Type

- Drive Unit

- General Use

- LPG Bottling Plant operations

- Material

- Mild Steel

- Type

- Industrial Drive Unit

- Capacity

- Customized as per requirement

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based

- Cooling System

- Air Cooled

- Purity(%)

- 99.5%

- Production Rate

- 500-5000 cylinders/day

- Dew Point

- -40C

- Air Consumption

- Minimized for efficiency

- Pressure

- High pressure suitable for LPG transfer

- Power Consumption

- Low

- Weight (kg)

- 350 kg

- Voltage

- 415 V

- Dimension (L*W*H)

- 1200 x 900 x 1000 mm

- Feature

- Corrosion resistant, High performance

- Color

- Blue

- Surface Finish

- Powder Coated

- Installation

- Skid Mounted for easy installation

- Operation Temperature

- 0°C to 50°C

- Drive Mechanism

- Heavy Duty Gear Assembly

- Safety Features

- Overload and short circuit protection

- Motor Type

- Three Phase Flange Mounted Electric Motor

- Compliance

- IS and international safety standards

- Noise Level

- < 70 dB

- Application

- Used for LPG cylinder filling and bottling plant automation

About Drive Unit LPG Bottling Plant

Buy from us an energy efficient Drive Unit LPG Bottling Plant designed to safely deliver power to LPG cylinder filling machines. It is equipped with a robust and sturdy electric motor and transmission gearbox for smooth transfer of rotational power at variable speed and torque. It is designed and developed as per automotive standards that lead to high robustness and working efficiency. The setup of this power source is mounted on a rigid mild steel frame that provides high strength and rigidity to bear extreme loads and vibrations produced during operation. The offered Drive Unit LPG Bottling Plant can be delivered to our customers as per the order placed by them.

Efficient and Automated LPG Cylinder Filling

Designed for streamlined LPG bottling plant automation, this drive unit utilizes computerized PLC-based controls to deliver fast, accurate cylinder filling. The automatic system allows handling of 5005000 cylinders per day, improving productivity while minimizing manual intervention and optimizing air and power consumption for operational efficiency.

Robust Construction & Safety Features

Fabricated from powder-coated mild steel, the drive unit is corrosion resistant and built for longevity in challenging plant environments. It offers advanced safety mechanisms, including overload and short circuit protection, and complies with IS and international safety regulations for safe, reliable operation during high pressure LPG transfer processes.

Simple Installation and Maintenance

The skid-mounted design simplifies placement and reduces setup time, making installation flexible and efficient for various plant layouts. Air-cooled mechanisms and streamlined procedures enable hassle-free maintenance, ensuring consistent performance with a low overall operating cost.

FAQs of Drive Unit LPG Bottling Plant:

Q: How is the Drive Unit installed in an LPG Bottling Plant environment?

A: The Drive Unit comes skid mounted, which means it can be easily placed and installed without the need for complex foundation work. This feature supports quick integration into existing bottling lines, simplifying the overall installation process and reducing downtime.Q: What safety features are included in this drive unit for LPG operations?

A: This unit is equipped with overload and short circuit protection systems, designed to automatically detect and respond to electrical anomalies. These features, along with compliance to IS and international safety standards, ensure operator safety and help prevent equipment damage.Q: When should this Drive Unit be used in LPG bottling plant processes?

A: The Drive Unit is ideal for the automated filling stage in LPG bottling plants, especially needed when high throughput and precision are required. It ensures smooth, reliable operation throughout continuous production cycles, supporting custom capacities based on plant requirements.Q: Where can this Drive Unit be integrated within LPG cylinder filling operations?

A: It is designed for use in industrial LPG bottling plants, particularly where there is a need to automate cylinder transfer, filling, and handling processes. Its flexible mounting system allows for installation in diverse plant configurations across India and other international markets.Q: How does the automated PLC-based control enhance operational efficiency?

A: The PLC-based control system manages and automates cylinder filling with precision, reducing manual intervention and improving consistency. It enables real-time monitoring and adjustment, optimizing air and power consumption, and boosting overall plant productivity.Q: What are the main benefits of using this Drive Unit in LPG bottling plants?

A: Benefits include high performance, corrosion resistance, low noise (below 70 dB), minimized air and power consumption, and the ability to handle a production rate from 500 to 5000 cylinders per day. The units air cooled system and powder-coated finish further increase durability and safety in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

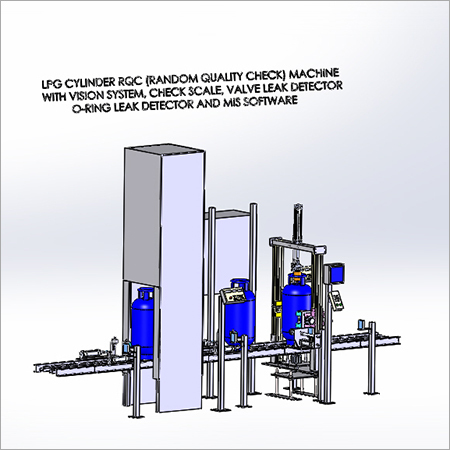

RQC MACHINE

Minimum Order Quantity : 1 Unit

Product Type : RQC Machine

Dimension (L*W*H) : 1200 x 850 x 1700 mm

Capacity : 1000 kg/hr

Weight (kg) : 650 kg

Production Rate : Continuous

EJECTION UNIT

Minimum Order Quantity : 1 Unit

Product Type : Injection Molding Ejection Unit

Dimension (L*W*H) : Custom as per machine integration

Capacity : Customizable as per mold size and tonnage

Weight (kg) : Varies with model, typically 75 300 kg

Production Rate : Depends on molding cycle, typically up to 1060 cycles/min

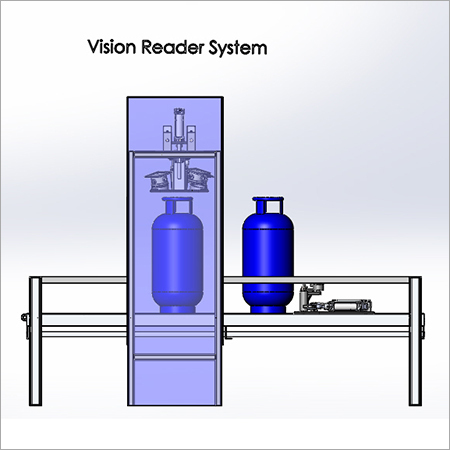

Vision Reader System

Minimum Order Quantity : 1 Unit

Product Type : Vision Reader System

Dimension (L*W*H) : 750 x 550 x 600 mm

Capacity : Varies as per application

Weight (kg) : 35 kg

Production Rate : Up to 150 units/hour

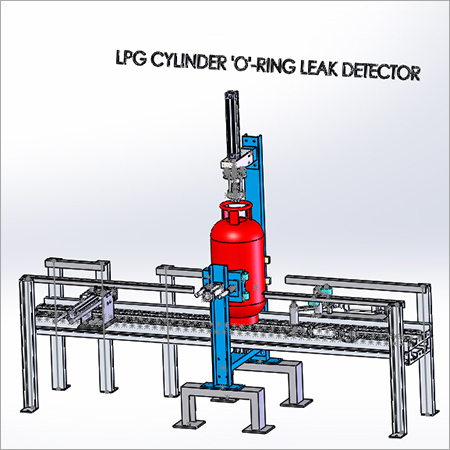

O-RING LEAK DETECTOR

Minimum Order Quantity : 1 Unit

Product Type : Leak Detector for ORing Testing

Dimension (L*W*H) : 400 mm x 300 mm x 350 mm

Capacity : Up to 5 Samples per Cycle

Weight (kg) : 20 Kg Approx.

Production Rate : Up to 60 Tests/Hour

Send Inquiry

Send Inquiry