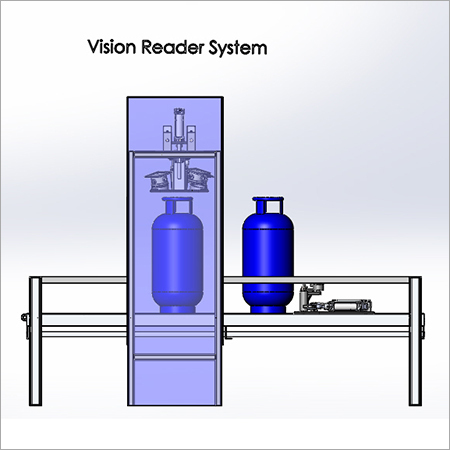

Vision Reader System

Vision Reader System Specification

- Product Type

- Vision Reader System

- General Use

- Industrial Vision Inspection

- Material

- Mild Steel and Aluminum Body

- Type

- Image Processing Equipment

- Capacity

- Varies as per application

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based Control

- Cooling System

- Air Cooled

- Production Rate

- Up to 150 units/hour

- Pressure

- Standard

- Power Consumption

- 120 W

- Weight (kg)

- 35 kg

- Voltage

- 220 V AC

- Dimension (L*W*H)

- 750 x 550 x 600 mm

- Feature

- High Accuracy, User Friendly Interface, Real Time Data

- Color

- Grey-Black

About Vision Reader System

Vision Reader System is a computer-based visual inspection system that is commonly used to check marking and labeling on LPG cylinders. It is installed with a premium-grade camera and image processing technologies to deliver high-end results. The computer system of this industrial-grade inspection unit can be programmed for different types of approved labels and markings. Vision Reader System standard alternating voltage of 220 to 440 volts for efficient and controlled functioning. It also has a database system to store a large number of records which leads to improved inventory accuracy and tracking. Get this heavy-duty test unit at a reasonable price.

Precision Visual Inspection for Industrial Needs

Tailored for industrial environments, the Vision Reader System leverages high-resolution imaging and powerful lighting to deliver accurate and reliable inspection results. Its robust construction and automated controls ensure consistent quality, enhancing both efficiency and productivity across various applications.

Flexible Integration and Seamless Operation

With multiple installation options including table and floor mounting, the Vision Reader System adapts effortlessly to varied production setups. The user-friendly touch screen, real-time data processing, and versatile communication protocols allow operators to streamline workflows and connect seamlessly with existing systems.

FAQs of Vision Reader System:

Q: How does the Vision Reader System ensure accurate image inspection?

A: The Vision Reader System utilizes a high-resolution 5 MP camera and LED bar/spot lighting for precise image capture, combined with advanced PLC-based controls, automatic processing, and real-time data output to deliver consistently accurate inspection results.Q: What types of environments is this system suitable for?

A: Designed for industrial applications, the Vision Reader System operates reliably in temperatures ranging from 0C to 50C and is constructed using durable mild steel and aluminum materials, making it ideal for demanding production lines and manufacturing facilities.Q: When should maintenance be performed on the Vision Reader System?

A: Regular maintenance is recommended in accordance with your facilitys standard equipment schedule. The air-cooled design and tough build minimize wear, but periodic checks on cleaning the camera lens, verifying power and connection integrity, and assessing software updates help maintain optimal performance.Q: Where can the Vision Reader System be installed within a facility?

A: The system provides flexible installation options, including table mount and floor mount configurations, allowing it to fit seamlessly into various production area layouts according to space and workflow requirements.Q: What are the steps involved in setting up the Vision Reader System for operation?

A: Installation involves securely mounting the unit on a chosen table or floor space, connecting it to power (220 V AC), and integrating it with the facilitys PLC and computer systems. The touch screen interface guides users through the software setup, calibration of image parameters, and selection of data output formats.Q: How is the Vision Reader System typically used in industrial settings?

A: Operators use the system for high-speed visual inspections, leveraging its automatic and computerized controls to detect defects or variations in products. Data is processed in real time and exported in CSV, XML, or directly to databases, supporting efficient quality assurance workflows.Q: What benefits does the Vision Reader System offer to manufacturers and traders?

A: Its high accuracy, rapid detection speed, and user-friendly interface contribute to improved product quality, reduced manual inspection labor, and enhanced operational efficiency. With customizable capacity and real-time reporting, businesses can optimize production outcomes and maintain competitive standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

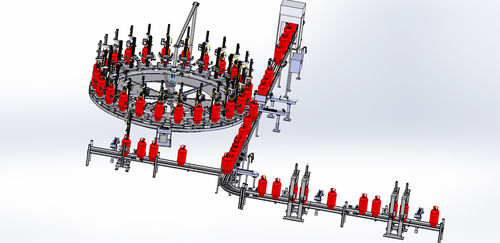

LPG Carousel 10 AND 24 Point

Minimum Order Quantity : 1 Unit

Product Type : LPG Filling Carousel

Material : Other, Mild Steel/SS/Customized

Capacity : 1236 Cylinders/Minute (Depending on Model)

General Use : Filling of LPG Cylinders in Bottling Plants

Power Consumption : 3 12 kW

EJECTION UNIT

Minimum Order Quantity : 1 Unit

Product Type : Injection Molding Ejection Unit

Material : Other, Alloy steel, Hardened components

Capacity : Customizable as per mold size and tonnage

General Use : Ejecting molded parts from cavity

Power Consumption : 27 kW (Depending on size and configuration)

INTRODUCTION UNIT

Product Type : Introduction Unit

Material : Other, Mild Steel

Capacity : 50 Nm3/hr to 1000 Nm3/hr

General Use : Industrial Air Separation

Power Consumption : 8 25 kW

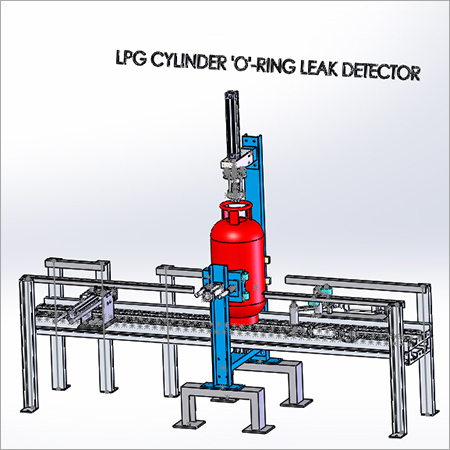

O-RING LEAK DETECTOR

Minimum Order Quantity : 1 Unit

Product Type : Leak Detector for ORing Testing

Material : Other, Stainless Steel and Aluminum Body

Capacity : Up to 5 Samples per Cycle

General Use : For Checking ORing and Rubber Component Leakage

Power Consumption : Not Required (Pneumatic)

Send Inquiry

Send Inquiry