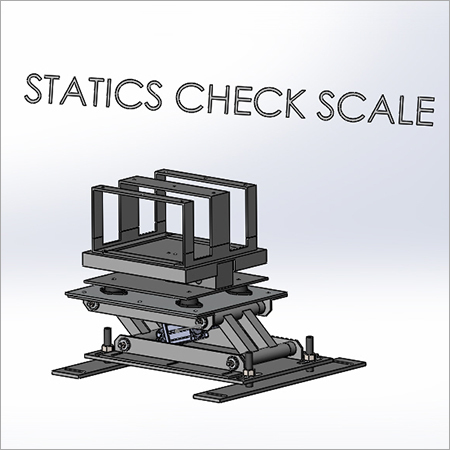

Check Scale 2020

Check Scale 2020 Specification

- Product Type

- Check Scale

- General Use

- Industrial Weight Checking

- Material

- Stainless Steel

- Type

- Digital Scale

- Capacity

- 30 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Production Rate

- High

- Pressure

- Standard Atmospheric

- Power Consumption

- 10W

- Weight (kg)

- 30 kg

- Voltage

- 230V AC

- Dimension (L*W*H)

- 550 x 450 x 780 mm

- Feature

- High Accuracy, Robust Body, Easy Operation

- Color

- Silver

- Platform Size

- 400 x 300 mm

- Resolution

- 1g

- Protection Level

- IP65

- Power Supply

- AC Adapter, 50/60 Hz

- Application

- For packaging lines, Quality Control, Assembly lines

- Display Type

- LED Digital Display

- Operating Temperature

- 0°C to 45°C

About Check Scale 2020

The offered Check Scale 2020 is a type of robust and sturdy checkweigher that can be used in a wide range of industries to measure the weight of different types of products during production processes. It can be used with conveyor machines and other heavy-duty equipment within the production line. This weight-measuring unit is fabricated by using top-grade alloyed materials that provide high strength and rigidity to bear extreme loads and vibrations. Check Scale 2020 greatly improves to reduce waste as well as improves production efficiency. Get this industrial unit as per your requirements with an assurance of fast and safe delivery.

Exceptional Accuracy and Reliability

With a fine 1g resolution and high-precision LED display, the Check Scale 2020 provides rapid and reliable weight measurements. Its robust stainless steel body assures longevity while the IP65 rating ensures resilience against dust and water ingress, perfect for demanding industrial settings.

Designed for Industrial Efficiency

Engineered for heavy-duty tasks, this scale delivers high production rates with minimal energy consumption of only 10W. Its platform accommodates various items for packaging, assembly, or quality inspections, optimizing workflow and reducing operational delays.

FAQs of Check Scale 2020:

Q: How does the Check Scale 2020 ensure high accuracy in industrial weight checking?

A: The scale utilizes an LED digital display with a 1g resolution, enabling precise and clear readings. Its advanced sensing technology and robust stainless steel platform minimize errors even in fast-paced industrial environments.Q: What are the benefits of using an IP65-rated scale in packaging and quality control lines?

A: The IP65 protection level means the scale is resistant to dust and water, reducing maintenance needs and ensuring consistent operation in harsh industrial settings like packaging and quality control lines.Q: When should the Check Scale 2020 be used in an industrial process?

A: It is most beneficial during weight verification stages in packaging lines, assembly processes, or quality control routines, especially when high accuracy and rapid throughput are required.Q: Where can the Check Scale 2020 be installed for optimal performance?

A: Install the scale on stable, flat surfaces within manufacturing, packaging, or quality control zones. The robust build and compact dimensions make it ideal for various industrial environments across India.Q: What is the process for operating the Check Scale 2020?

A: Operation is straightforward: connect the AC adapter, ensure the scale is clean, place items on the platform, and read the measurement on the LED display. Manual control allows easy adjustment and operation as per user requirements.Q: Can the Check Scale 2020 be integrated into automated assembly lines?

A: While the scale features automatic weighing functions, it is controlled manually and cannot be computerized or directly integrated into fully automated systems. However, it can complement such lines where manual intervention is feasible.Q: What advantages does the stainless steel construction provide for industrial applications?

A: Stainless steel ensures durability, resistance to corrosion, and the ability to withstand daily industrial wear and tear. This makes the scale suitable for rigorous use in packaging and quality control environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

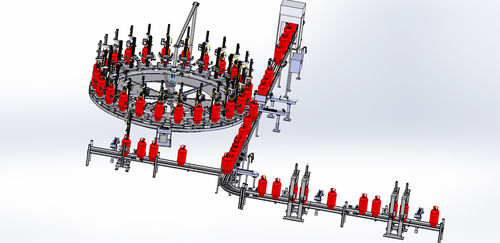

LPG Carousel 10 AND 24 Point

Minimum Order Quantity : 1 Unit

Product Type : LPG Filling Carousel

Feature : Other, High Precision, Robust Design, Low Maintenance, Customizable Points

Pressure : 1017 Bar (Working Pressure)

General Use : Filling of LPG Cylinders in Bottling Plants

Control System : Other, PLC Based Control Panel

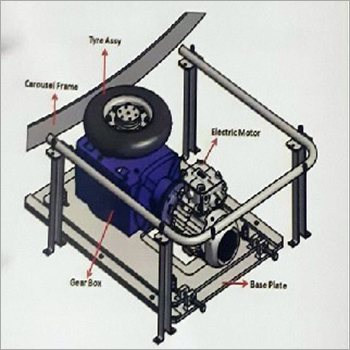

Drive Unit LPG Bottling Plant

Minimum Order Quantity : 1 Unit

Product Type : Drive Unit

Feature : Other, Corrosion resistant, High performance

Pressure : High pressure suitable for LPG transfer

General Use : LPG Bottling Plant operations

Control System : Other, PLC based

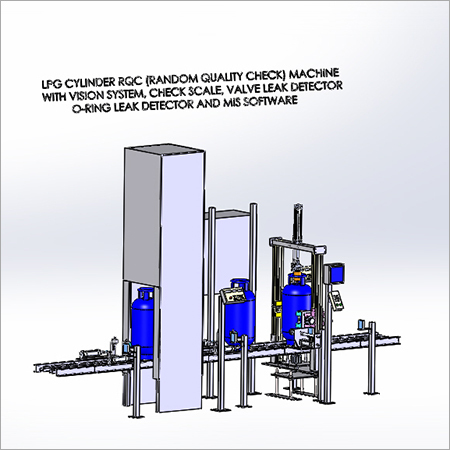

RQC MACHINE

Minimum Order Quantity : 1 Unit

Product Type : RQC Machine

Feature : Other, High Accuracy and Durability

Pressure : 7 Bar

General Use : Rubber Quality Control

Control System : Other, PLC Control

EJECTION UNIT

Minimum Order Quantity : 1 Unit

Product Type : Injection Molding Ejection Unit

Feature : Other, Precise repetitive motion, low cycle time, durable design

Pressure : Highpressure hydraulic system

General Use : Ejecting molded parts from cavity

Control System : Other, Manual/Servo control options

Send Inquiry

Send Inquiry