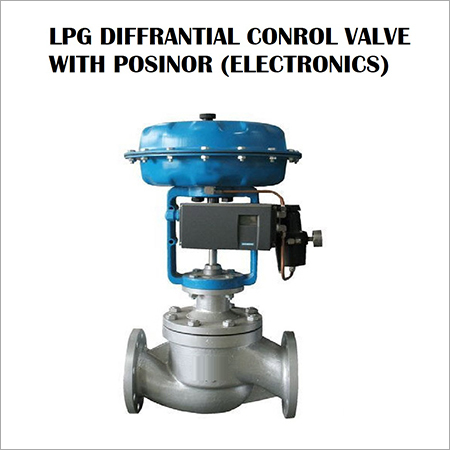

DIFFRANTIAL CONTROL VALVE

DIFFRANTIAL CONTROL VALVE Specification

- Product Type

- Differential Control Valve

- General Use

- Flow and Pressure Regulation in HVAC and Industrial Systems

- Material

- Cast Iron / Ductile Iron / Stainless Steel

- Type

- Hydronic/Water Control Valve

- Capacity

- DN 15 to DN 300 sizes

- Computerized

- No

- Automatic

- Yes

- Control System

- Differential Pressure Based

- Production Rate

- Continuous

- Pressure

- Up to 16 Bar

- Weight (kg)

- Varies by model (approx. 8-120 kg)

- Dimension (L*W*H)

- Varies by model (e.g., DN65: approx. 341mm x 206mm x 197mm)

- Feature

- Automatic Pressure Balancing, Stable Flow Control

- Color

- Blue / Customized

- End Connection

- Flanged / Screwed Options

- Application

- HVAC Systems, District Cooling, Water Distribution, Chilled Water Circuits

- Body Coating

- Epoxy Powder Coated Finish

- Max. Working Temperature

- Up to 120°C

- Seal Material

- EPDM / PTFE

- Connection Type

- Flanged Ends as per DIN/ANSI Standards

- Mounting Position

- Horizontal/Vertical

- Actuator Option

- Manual, Pneumatic or Electric on request

- Compliance

- ISO 9001:2015 Certified

- Flow Range

- Depending on Valve Size and Model

- Media

- Water, Glycol Solutions

About DIFFRANTIAL CONTROL VALVE

DIFFRANTIAL CONTROL VALVE is a robust fluid control unit that is designed to control pressure differences across the valve. The body of this flow control unit is fabricated by using top-quality alloyed steel that gives high strength and rigidity to resist extreme pressure and temperature. The control element of this industrial valve is connected to an electrical system that delivers control signals to pneumatic, hydraulic, or electric units for efficient and controlled functioning. DIFFRANTIAL CONTROL VALVE availed by our company is specially designed for LPG bottling systems but it can also be used in other applications such as heating, cooling, and air conditioning systems.

Reliable Flow and Pressure Management

This valve incorporates a differential pressure-based control system, automatically balancing pressure and maintaining stable flow rates, which is critical in large-scale HVAC and water distribution systems. Options for manual, pneumatic, or electric actuators provide flexible integration and optimized operation for diverse applications.

Crafted for Enduring Performance

Its robust body, available in cast iron, ductile iron, or stainless steel, is protected with an epoxy powder-coated finish, enhancing resistance against corrosion. EPDM and PTFE seals ensure leak-proof operation under varying thermal loads, while compliance with ISO 9001:2015 guarantees consistent manufacturing quality.

FAQs of DIFFRANTIAL CONTROL VALVE:

Q: How does the differential control valve regulate flow and pressure in HVAC systems?

A: The valve employs a differential pressure-based system to automatically balance and regulate the flow and pressure. This ensures consistent distribution of water or glycol solutions within HVAC networks, reducing system inefficiencies and optimizing energy use.Q: What connection options are available for installation?

A: The valve can be supplied with flanged ends as per DIN/ANSI standards, and alternatively with screwed connections. This allows versatile mounting in horizontal or vertical positions, adapting easily to piping layouts in various industrial and commercial settings.Q: When should I choose EPDM or PTFE sealing material for my application?

A: EPDM seals are best for water and mild glycol applications up to 120C, offering reliable flexibility and thermal resilience. PTFE is preferable where higher chemical resistance or temperature stability is needed, especially in demanding environments.Q: Where can the differential control valve be applied beyond HVAC and district cooling?

A: These valves are also suitable for water distribution and chilled water circuits in both commercial buildings and industrial facilities, providing automatic pressure adjustment and flow control wherever precise hydronic regulation is required.Q: What is the process to request an actuator for automatic control?

A: When ordering, specify your preferred actuator typemanual, pneumatic, or electric. The valve will be factory-fitted or supplied ready for actuator mounting, enabling easy transition to automated or remote flow management as per your control requirements.Q: What are the benefits of using epoxy powder-coated valves in water systems?

A: Epoxy coating provides enhanced protection against corrosion and mechanical wear, extending operational lifespan and maintaining valve performance even in tough environmental conditions, particularly important for continuous-operation systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

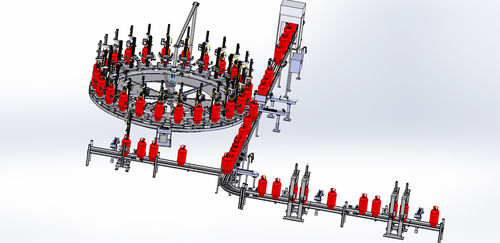

LPG Carousel 10 AND 24 Point

Minimum Order Quantity : 1 Unit

Product Type : LPG Filling Carousel

Voltage : 380415 V, 3 Phase, 50 Hz

Type : Rotary Carousel (10 & 24 Point Available)

Capacity : 1236 Cylinders/Minute (Depending on Model)

Weight (kg) : Approx. 2000 kg (10 Point); 3500 kg (24 Point)

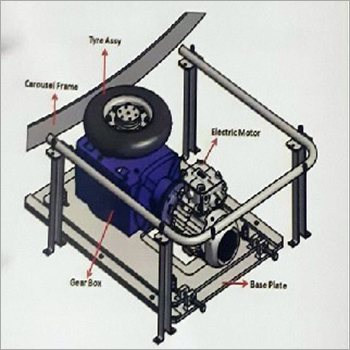

Drive Unit LPG Bottling Plant

Minimum Order Quantity : 1 Unit

Product Type : Drive Unit

Voltage : 415 V

Type : Industrial Drive Unit

Capacity : Customized as per requirement

Weight (kg) : 350 kg

EJECTION UNIT

Minimum Order Quantity : 1 Unit

Product Type : Injection Molding Ejection Unit

Voltage : 230V/415V, 3 Phase, 50 Hz

Type : Hydraulic Ejection Unit

Capacity : Customizable as per mold size and tonnage

Weight (kg) : Varies with model, typically 75 300 kg

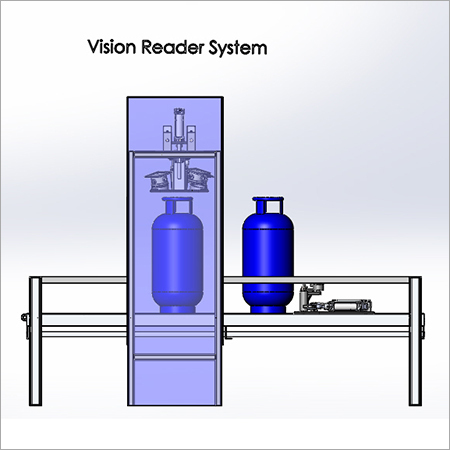

Vision Reader System

Minimum Order Quantity : 1 Unit

Product Type : Vision Reader System

Voltage : 220 V AC

Type : Image Processing Equipment

Capacity : Varies as per application

Weight (kg) : 35 kg

Send Inquiry

Send Inquiry