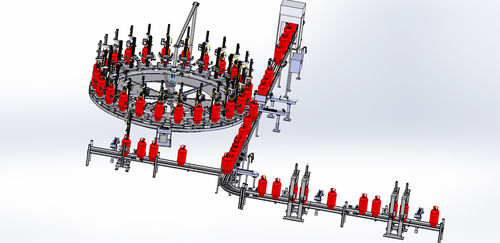

LPG Carousel 10 AND 24 Point

LPG Carousel 10 AND 24 Point Specification

- Product Type

- LPG Filling Carousel

- General Use

- Filling of LPG Cylinders in Bottling Plants

- Material

- Mild Steel/SS/Customized

- Type

- Rotary Carousel (10 & 24 Point Available)

- Capacity

- 12-36 Cylinders/Minute (Depending on Model)

- Computerized

- Yes

- Automatic

- Semi-Automatic / Fully Automatic (Optional)

- Control System

- PLC Based Control Panel

- Purity(%)

- 99%

- Production Rate

- Up to 1,500 Cylinders per Hour for 24 Point

- Air Consumption

- 6-10 Nm/hr (Depending on Model)

- Pressure

- 10-17 Bar (Working Pressure)

- Power Consumption

- 3 - 12 kW

- Weight (kg)

- Approx. 2000 kg (10 Point); 3500 kg (24 Point)

- Voltage

- 380-415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 3700 mm x 3700 mm x 2200 mm (10 Point); 6400 mm x 6400 mm x 2200 mm (24 Point)

- Feature

- High Precision, Robust Design, Low Maintenance, Customizable Points

- Color

- Industrial Blue/Grey or as per Client Requirement

LPG Carousel 10 AND 24 Point Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 40 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

- Certifications

- PESO CERTIFIED

About LPG Carousel 10 AND 24 Point

LPG Carousel system design to fill LPG cylinder. Every individual filling scale has own intrinsically safe display terminal which is certified by peso. It is load cell based and had a coarse and fine filling process. This is process by 12VDC intrinsically safe solenoid valve.Capacity to fill by 10 point Carousel output per Hour 692 Cylinder (max) and 24 point Carousel Output per Hour 1661 Cylinder (Max)

Optimized for Bottling Plant Efficiency

Engineered for LPG bottling and filling operations, these carousels significantly accelerate cylinder handling. The array of filling points, coupled with automated and computerized controls, streamline the workflow, reduce downtime, and boost output capacity for both small and large-scale operations.

Safety and Compliance Assured

Both the 10 and 24 Point models incorporate a suite of safety features, such as emergency stops, interlocks, and overload protection. Fully certified to PESO, ATEX, and CE standards, these rotary carousels offer peace of mind and regulatory compliance for industrial use.

Tailored to Your Production Requirements

Choose between several customization options, including number of filling points, filling head type, capacity, and physical dimensions. Cylinders of varying diameters and heights are readily accommodated, making these carousels versatile solutions for fluctuating industry demands.

FAQs of LPG Carousel 10 AND 24 Point:

Q: How does the LPG Carousel enhance the filling process in bottling plants?

A: The LPG Carousel automates the cylinder filling process, enabling simultaneous filling at multiple points. This improves throughput and consistency, minimizing manual intervention and significantly increasing overall efficiency for LPG bottling operations.Q: What cylinder sizes are compatible with the 10 and 24 Point models?

A: Both models accommodate cylinder diameters ranging from 250 mm to 400 mm and heights from 400 mm to 1300 mm, making them suitable for a broad spectrum of LPG cylinders commonly used in the industry.Q: What safety measures are included in the carousel system?

A: Every LPG Carousel features emergency stop functions, interlocks, and overload protection, ensuring operational safety. The system also adheres to PESO, ATEX, and CE certifications, further guaranteeing safe use in industrial environments.Q: Where are these carousel systems typically installed?

A: These rotary carousels are primarily designed for use within LPG bottling and filling plants, where rapid and precise cylinder filling is essential for daily operations.Q: What benefits do automated and PLC-based controls offer?

A: The integrated PLC-based control panel enables semi-automatic or fully automatic operation, providing precise regulation, monitoring, and adjustment of the filling process. This reduces human error and enables safer and more reliable performance.Q: Can the carousel be customized for specific plant requirements?

A: Yes, clients can specify the number of filling points, choose between single or double filling heads, select preferred materials, and request custom colors and dimensions to suit unique facility requirements.Q: What is the production capacity of the 24 Point Carousel model?

A: The 24 Point model can fill up to 1,500 cylinders per hour, delivering a capacity of 1236 cylinders per minute, depending on the specific configuration and operating parameters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines And Equipments For Lpg Bottling Plants Category

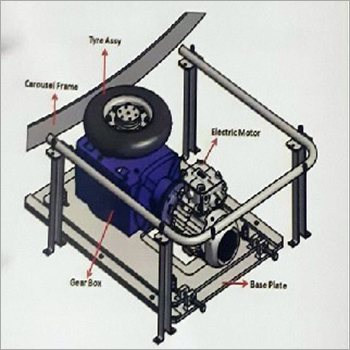

Drive Unit LPG Bottling Plant

Minimum Order Quantity : 1 Unit

Product Type : Drive Unit

Capacity : Customized as per requirement

Feature : Other, Corrosion resistant, High performance

Type : Industrial Drive Unit

Color : Blue

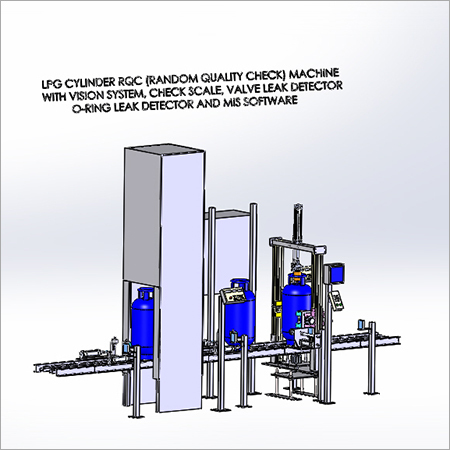

RQC MACHINE

Minimum Order Quantity : 1 Unit

Product Type : RQC Machine

Capacity : 1000 kg/hr

Feature : Other, High Accuracy and Durability

Type : Testing Equipment

Color : Blue and White

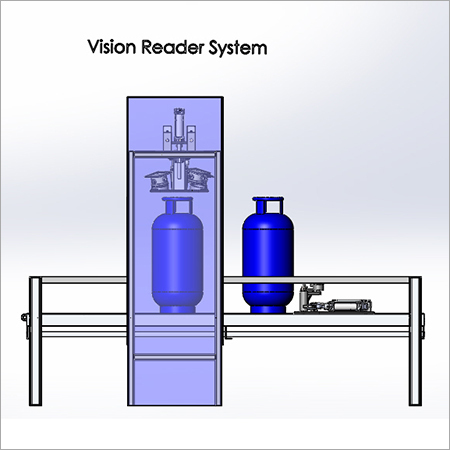

Vision Reader System

Minimum Order Quantity : 1 Unit

Product Type : Vision Reader System

Capacity : Varies as per application

Feature : Other, High Accuracy, User Friendly Interface, Real Time Data

Type : Image Processing Equipment

Color : GreyBlack

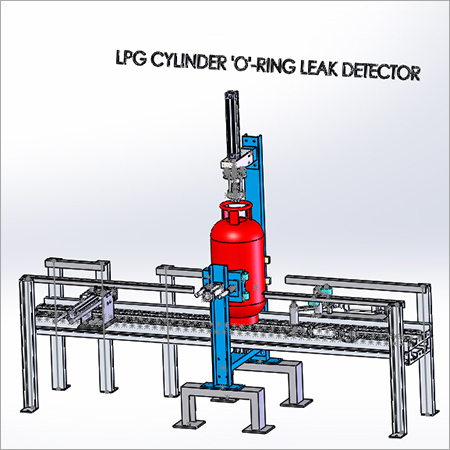

O-RING LEAK DETECTOR

Minimum Order Quantity : 1 Unit

Product Type : Leak Detector for ORing Testing

Capacity : Up to 5 Samples per Cycle

Feature : Other, Easy Operation, High Accuracy Detection, Compact Design

Type : Bench Top Model

Color : Silver & Black

Send Inquiry

Send Inquiry